Introduction

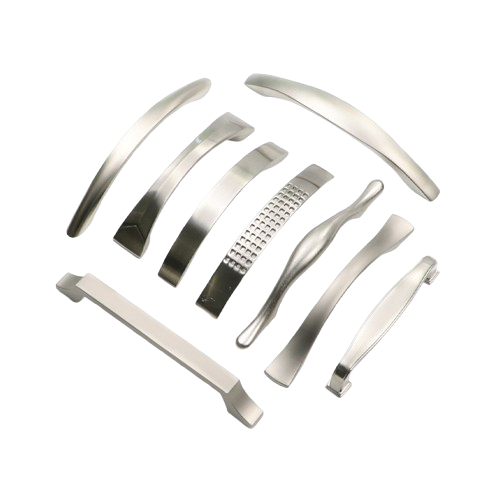

Furniture handles are key functional components of household items. They are mainly used for opening, adjusting or fixing cabinet doors, drawers, window frames and other parts. Through material, shape and process design, they achieve the unity of functionality and aesthetics

Material

Stainless steel furniture handles, aluminum alloy furniture handles, zinc alloy furniture handles

Function

Hinged handles: traditional door opening and closing, need to be used with hinges.

Sliding handles: embedded in the groove, no protruding design, saving space

Hidden handles: push-type or magnetic suction type, no trace on the surface, strong sense of technology

Furniture Handles Manufacturer and Supplier

High-quality materials

Environmentally friendly and durable materials such as aluminum alloy/stainless steel/solid wood are corrosion-resistant and have strong load-bearing capacity, suitable for a variety of home styles.

Ergonomic design

Optimize the grip arc and thickness to reduce hand fatigue, suitable for high-frequency use scenarios (such as kitchens and bathrooms).

Precise mold adaptation

The independent mold system ensures accurate dimensions, seamlessly matches the plate slots, and is integrated after installation.

Multi-style coverage

Modern minimalism, retro carvings, chrome-plated metal and other 10+ styles are optional, support personalized customization, and are suitable for villas, apartments, and office spaces.

Cost-effective supply

Scaled production + vertical supply chain, significant cost advantages, more competitive prices at the same quality.

Full-process quality control guarantee

8 quality inspection levels + SGS/BIFMA certification, defective product rate ≤0.5%, providing worry-free after-sales service.

Wuparts focuses on the research and development of hardware furniture handles, with precision molds and innovative technology as its core competitiveness

CNC stamping molding

One-piece molding with imported German equipment, 40% efficiency improvement, smooth edges without burrs, and stable process.

Micro-electrolytic chrome plating process

Abrasion resistance is increased by 3 times, and the salt spray test exceeds 2000 hours, which is comparable to the automotive grade standard.

Quick installation patented structure

Install in seconds without tools, adapt to standard/non-standard hole spacing, and shorten the installation time by 50%.

Green and environmentally friendly production

Water-based paint + solar power supply, VOC emissions are only 1/3 of the national standard, and ISO14001 certified.

AI intelligent process optimization

MES system monitors parameters in real time, AI dynamic tuning, and the yield rate is stable at 98.8%.

Flexible small batch production

Quick changeover in 30 minutes, support 500 pieces of minimum order, to meet the personalized needs of customers.

Custom Furniture Handles

How to Customize Furniture Handles at Wuparts?

We offer end-to-end customization services, adjusting materials, dimensions, functions (e.g., noise reduction/anti-collision), and installation methods. Prototype approval in as fast as 15 days, with bulk delivery within 30 days.

1

Demand matching

Communicate style/size/function requirements and clarify the design direction.

3

Production and stocking

Small batch fast production, simultaneous quality inspection and packaging.

2

Design confirmation

3D modeling + prototype proofing, customer signing and finalizing.

4

After-sales guarantee

Return and exchange defective products, provide technical support.

Furniture Handles Product Summary

Precision manufacturing, durable

——High-precision mold + innovative chrome plating process, wear-resistant and corrosion-resistant, suitable for a variety of plates, long service life.

Smart design, ready to use

——Modular quick-install structure, no tools required, suitable for standard/non-standard hole spacing, and supports personalized style customization.

Stainless steel cabinet handles

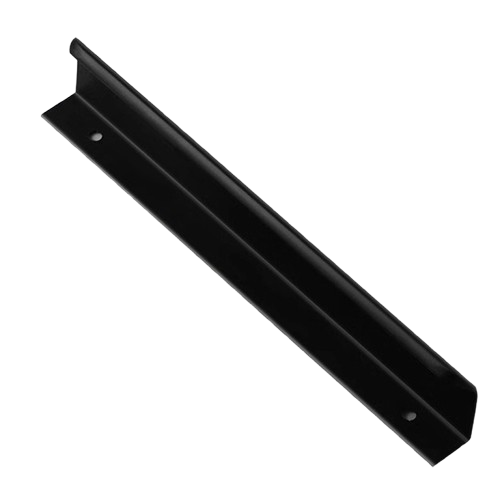

One-line furniture handles

Invisible embedded handles

Applications of Furniture Handles

wuparts provides differentiated product solutions for durability (such as kitchen), safety (such as bathroom) and comfort (such as bedroom) in different scenarios. Below are practical application scenarios:

01

Anti-fingerprint stainless steel/aluminum alloy handles, suitable for high temperature and high humidity environments such as next to range hoods and under stoves, need to be scratch-resistant and easy to clean.

02

Embedded invisible handles or slightly convex buckles, suitable for humid spaces such as shower rooms and mirror cabinets, require mildew resistance and no convex safety hazards.

03

Aluminum alloy narrow slit one-shaped handles or magnetic hidden buckles, suitable for sliding doors/swing doors, need to be silent and smooth, load-bearing ≥50kg, and reduce switching noise.

How to Choose Furniture Handles

Aesthetic Matching

Unified Material Style

Solid wood matches logs, metal matches modern, rejecting the sense of disobedience.

Neutral Color King

Black/Silver/Matte White, suitable for any decoration color system.

Styling echoes design language

Minimal style uses flat style, retro style adds carvings, less is more.

Proportion coordination space

Small apartment slender style, large space wide arc, more visually balanced.

Details hide ingenuity

Chinese style chooses cloud pattern, Nordic style uses geometry to strengthen cultural symbols.

Light and shadow dot the atmosphere

Transparent acrylic + LED lights, a sense of technology can be taken at will.

Practical Performance

Stainless steel>Aluminum alloy>Chrome plating

In humid environments, identify anti-fingerprint alloys, durable and durable.

Fully surrounded base is more stable

Single screws are easy to loosen, and the load-bearing capacity is ≥30kg to be safe.

Embedded>Snap-on>Surface-mounted

Tool-free installation, no need to pry screws for maintenance.

Micro-electrolytic chrome plating is easy to maintain

Oil stains can be wiped clean, and the salt spray test exceeds 2000 hours.

Rounded corners ≥ 2mm safety line

Anti-collision design, friendly to the elderly and children.

Buy with confidence with certification mark

SGS/BIFMA certification, quality guaranteed.

Client Testimonials

Our Achievments

At Wuparts, customer satisfaction is our top priority. We are committed to providing high-quality home hardware products that meet the highest standards.With a focus on quality, service, and innovation, we aim to be your reliable long-term home hardware supplier!

Years of experience

Satisfaction

Happy Customers

John Miller

Procurement Manager

“We have been sourcing hardware products from them in bulk for over a year, and the quality has been consistently outstanding. Their modern and practical designs make them a favorite among our clients. Highly recommended!”

Michael Brown

Wholesaler

“The kitchen accessories and hardware we source from them are always of the highest quality. They are reliable, durable, and meet our customers’ demands perfectly. A trusted supplier we’ll continue working with!”

Arjun Mehta

Purchasing Director

“As a bulk buyer for a fast-growing brand, I value reliable suppliers. Their products consistently exceed our expectations, whether it’s in design, quality, or performance. Truly a fantastic partner!”

Sarah Collins

Brand Manager

“Their kitchen products perfectly align with our brand’s values of quality and style. The durability and sleek design are always appreciated by our customers. We are proud to partner with them!”