Material Revolution: Looking at the Selection of Commercial-Grade Door Handle Materials from Laboratory Data

| Material | Tensile strength(MPa) | Corrosion resistance test (salt spray) | Maintenance cost index | Typical application scenarios |

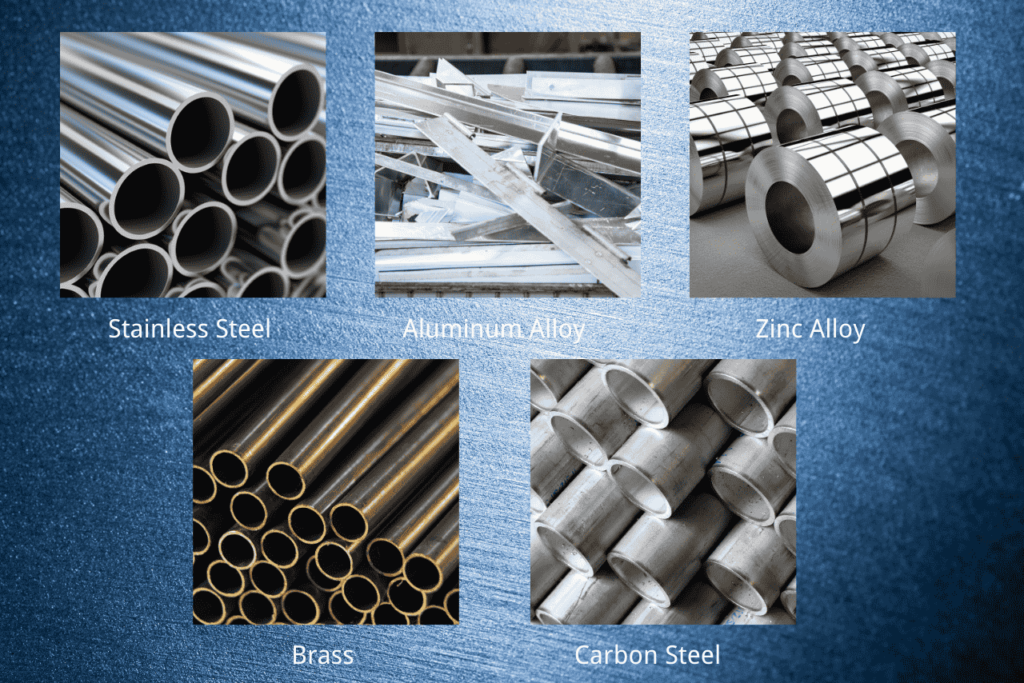

| 304 Stainless Steel | 520-700 | 96 hours rust-free | ★★☆☆☆ | Hospital ICU/Airport security channel |

| 6063-T5 Aluminum | 150-250 | 24 hours slight oxidation | ★★★★★ | Supermarket chain/office building |

| Brass Alloy | 200-300 | 12 hours surface oxidation | ★★☆☆☆ | High-end luxury store |

| Nylon + PC composite | 70-100 | 192 hours without change | ★★★★☆ | Subway station/Airport terminal |

Industry Truth:

Why has aviation-grade aluminum alloy become mainstream? WUPARTS WL606 series is anodized, with a surface hardness of HV1200, which is 400% higher than the traditional stainless steel anti-fingerprint performance (data source: SGS friction coefficient test report)

Beware of the “chrome plating trap”: low-priced chrome-plated door handles can suffer from intergranular corrosion within 3 months in an environment with humidity >60% (see ISO 8501-1 surface treatment standard)

Structural design: the perfect balance between anti-theft and aesthetics

The evolution of anti-theft technology

Mechanical anti-theft: WUPARTS patented “three insurance” structure (eccentric shaft design + anti-pull pin + thread locking)

Electronic integration solution: RFID access control + biometric module (suitable for government confidential departments, FCC/CE certified)

Ergonomic black technology

Grip optimization formula: D=2.5×(cross-sectional area of hand)+0.8×(frequency of use) (WUPARTS WH801 handle diameter 32mm, in line with BS EN ISO 13849 safety standard)

Silent technology breakthrough: using polyoxymethylene (POM) cushion, switching noise ≤28dB (compared to 35-45dB of traditional metal spring)

Scenario selection guide: 10 years of practical experience of engineers

| Scene Type | Recommended configuration | Cost Control Techniques | Maintenance cycle recommendations |

| Hospital operating room | 304 stainless steel + IP67 waterproof + antibacterial coating | Choose quick-release panel design to reduce replacement costs | Ultrasonic cleaning every 6 months |

| Hotel Rooms | Titanium alloy + frameless hidden design + luminous indicator | Modular installation, suitable for different door thicknesses | Quarterly lubrication maintenance |

| Industrial Plant | Hot-dip galvanized steel + explosion-proof sealing structure | Integrated pressure relief valve design to extend service life | Professional rust removal every year |

Typical case:

Singapore Changi Airport: using WUPARTS nylon composite door handles, successfully reducing the annual failure rate from 14.7% to 2.1%

New York Times Square flagship store: brass handle design with intelligent counting system to achieve 27% optimization of customer traffic flow

Installation pit avoidance guide: key details ignored by 90% of practitioners

Embedded parts error control

The door thickness tolerance must be controlled within ±1.5mm (refer to ISO 12100 Mechanical Safety Standard)

Use laser level to calibrate the installation plane (WUPARTS provides free digital calibration kit)

Sealing process upgrade

Traditional silicone sealant → epoxy resin + polyurethane two-component seal (temperature range -40℃~180℃)

WUPARTS patented “sandwich” sealing structure, waterproof level reaches ASTM E283 standard

Torque parameter standardization

Push and pull force is recommended to be controlled at 3-5N·m (too tight will cause metal fatigue, too loose will cause abnormal noise)

Use torque wrench for precise debugging (WUPARTS WL606 comes standard with a torque regulator)

Maintenance system construction: full life cycle cost model

Cost composition formula:

C=C(Purchase)×(1+1+ir)n+C(Maintenance)×∑k=1n(1+i)k1

(where: C=total cost, r=annual discount rate, i=inflation rate, n=service life)

WUPARTS service solution:

Predictive maintenance platform: Real-time monitoring of switch times and torque changes through IoT sensors

Circular economy model: The recycling rate of old handles can reach 85%, and carbon emissions are reduced by 42%

Conclusion

When commercial door handles are upgraded from “functional accessories” to “spatial strategic assets”, a scientific selection system should include:

Material fatigue test data for more than 10 years

Anti-collision performance through FMVSS 208 collision test

Sustainable supply chain that meets LEED EBOM standards

24/7 global technical support network

How to Select Durable Commercial Door Handles from WUPARTS?

Step 1: Accurate matching of needs

Scenario diagnosis: Provide project type (hospital/hotel/office building, etc.), door material (tempered glass/solid wood/metal door), average daily frequency of use and special needs (such as barrier-free design, explosion-proof level).

Technical parameter submission: Specify door thickness (5-12mm), handle hole spacing (standard/non-standard), material preference (304 stainless steel/6063-T5 aluminum/composite nylon) and certification requirements (such as EN 1143 anti-pry certification).

Step 2: Customized solution output

3D modeling and simulation: Generate handle structure simulation based on customer CAD drawings, and verify impact resistance through finite element analysis (FEA) (≥100,000 switch tests).

Sample verification: Provide A/B physical samples (including material test report, grip test data), and support 72-hour expedited proofing service.

Step 3: Intelligent production and quality control

Digital manufacturing: CNC machine tool processing (accuracy ±0.05mm) + automated electroplating production line is used to achieve a large-scale delivery capacity of 5 million pieces per year.

Six Sigma quality inspection: 5% of products are randomly sampled in each batch, and pass the salt spray test (5% NaCl solution, 96 hours without rust), torque test (3-5N·m standard value) and IP67 waterproof certification.

Step 4: Global logistics and installation

Supply chain collaboration: Relying on DHL’s global network and bonded warehouse advantages, we can achieve a time guarantee of 48 hours to Europe and 72 hours to Southeast Asia.

Intelligent installation system:

Provide AR assisted installation APP to automatically identify the hole position deviation of the door body (automatic calibration within ±1.5mm).

The local service team is equipped with a thermal imager to ensure that the installation torque and sealing performance meet the standards.

Step 5: Full life cycle service

Predictive maintenance: Monitor the number of switches and vibration spectrum through IoT sensors, and warn of potential failures 3 months in advance.

Green recycling program: The recycling rate of old handles is as high as 92%, and the new products made of recycled materials can trace the carbon footprint (65% lower than the carbon emissions of new products).

WUPARTS procurement advantages and highlights

Flexible supply chain: Support small batch customization (minimum order quantity 100 pieces), quick response to emergency orders (4-week delivery cycle).

Cost optimization model: LCC (Life Cycle Cost) calculator developed based on 10,000+ project data to help you reduce the total cost of ownership by 20%.

Compliance guarantee: Obtained multiple international certifications such as Lloyd’s Register (LR) and FMVSS 208, and meet the EU RoHS/REACH environmental protection directives.

Take action now

Click on the online procurement portal and submit your demand form to get:

✅ Free door handle performance evaluation report

✅ One-on-one consultation with exclusive account managers

✅ Priority sample testing channel